iriver automobile dash cam case study

iRiver came to our team at Phloy to get our help in designing their new dash mounted camera system, otherwise known as blackboxes in South Korea. We conducted some basic research and presented concepts to the iRiver team for approval and development.

1. research

Research for this project consisted of three parts. Part one is the market feasibility report, part two is the product matrix exercise, and part three was establishing the design language through mood boards.

It’s important to create a feasibility report to help where the product will slot into once it’s produced. We explored an adjacent marketplace, in this case, helmet cameras, to draw inspiration and features that might be useful for dash cams that doesn’t previously exist. We also did a full feature report on other dash cams in the market to keep our concept competitive.

The first matrix was an exercise in where the product might fit in the marketplace in terms of price and features. This is important to do, especially if the market is particularly saturated with similar goods with similar features and prices. This helped us to suggest features and a pricing scheme that might fit into a market niche that is currently unoccupied by another product. The second matrix was more of a design exercise where we tried to look for a spot in the marketplace where we could present a concept that wasn’t taken by another product. In this case, we identified five possible areas where we thought the concept might flourish in the intersections of conservative, youthful, feminine, and masculine design languages.

Mood boards provide a grounded design foundation for designers to start creating concepts out of. Designers use mood boards for design inspiration, design language guidance, as well as color, material, and finish choices.

2. Development

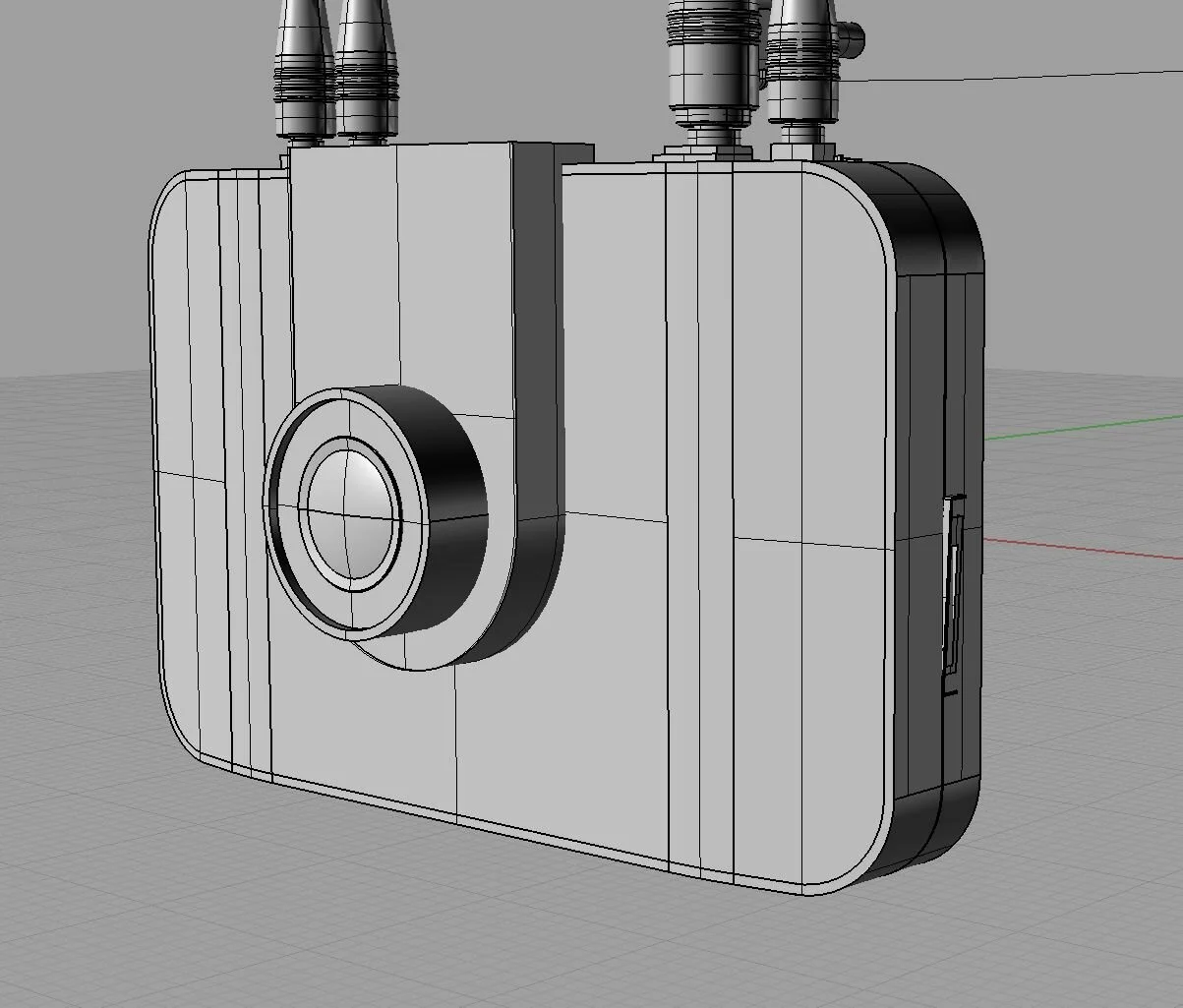

Development is the meat of the project. This project’s development cycle was split into three parts: Sketch, 3D Modeling, and Rendering.

Sketches are the fastest way to explore forms, shapes, and design languages outside of colors and materials, and finishes. With a solid understanding of the desired form language, we can move on to 3d sketches, while understanding the limitations of the hardware that was presented by the client. In this case, the LCD shape, size, thickness, PCB, PCB components, and batteries were all hard set by the client.

We explored forms while restrained by the shape and size of the LCD and internal components.

3. renderings and handoff

This is the final step. We continued to refine the designs and came up with three final designs that were presented to the client.